濟南鑫魯泉盛機械設(shè)備有限公司

濟南鑫魯泉盛機械設(shè)備有限公司

服務(wù)熱線:15662735099

聯(lián)系地址:山東章丘棗園經(jīng)濟開發(fā)區(qū)

倉泵氣力輸送技術(shù)的核心特點是什么?

倉泵氣力輸送技術(shù)作為一種先進的物料搬運方案

,憑借其獨特的技術(shù)優(yōu)勢,在工業(yè)生產(chǎn)中扮演著不可或缺的角色。該技術(shù)以壓縮空氣為動力源,通過密閉管道實現(xiàn)粉狀、顆粒狀物料的高效輸送,其特點可歸納為以下四個維度。As an advanced material handling solution, bin pump pneumatic conveying technology plays an indispensable role in industrial production with its unique technological advantages. This technology uses compressed air as the power source and achieves efficient transportation of powdered and granular materials through closed pipelines. Its characteristics can be summarized into the following four dimensions.

一

、全密閉輸送,環(huán)保性能卓越1

、 Fully enclosed transportation, excellent environmental performance傳統(tǒng)機械輸送方式常因設(shè)備密封不嚴導(dǎo)致粉塵泄漏

,而倉泵氣力輸送系統(tǒng)采用全封閉式設(shè)計,物料從進料到卸料全程與外部環(huán)境隔離。以水泥行業(yè)為例,應(yīng)用該技術(shù)后,生產(chǎn)現(xiàn)場粉塵濃度可控制在國家標準以內(nèi),徹底解決物料散落污染問題。此外The traditional mechanical conveying method often leads to dust leakage due to inadequate equipment sealing, while the pneumatic conveying system of the bin pump adopts a fully enclosed design, isolating the entire process of material from feeding to unloading from the external environment. Taking the cement industry as an example, after applying this technology, the dust concentration on the production site can be controlled within the national standard, completely solving the problem of material scattering pollution. In addition, sealed pipelines effectively prevent the risk of material deterioration such as moisture and weathering, and are particularly suitable for fields such as food and medicine that require strict cleanliness.

二

2、 Strong spatial adaptability and flexible layout

倉泵氣力輸送系統(tǒng)突破傳統(tǒng)輸送設(shè)備的空間限制

The pneumatic conveying system of the silo pump breaks through the spatial limitations of traditional conveying equipment and can easily achieve vertical lifting, horizontal crossing, and multi bend turning. In the power industry, a coal-fired power plant uses this technology to transport boiler ash from the underground negative layer to a hundred meter high ash silo. The pipeline is flexibly arranged along the plant structure without the need for additional transfer stations. For complex terrains in chemical industrial parks, the system can adjust the airflow speed through frequency conversion control to ensure that materials maintain a stable flow state during long-distance transportation, and the pipeline wear rate is reduced by more than 70% compared to traditional methods.

三、高效節(jié)能

3

該技術(shù)通過優(yōu)化氣流壓力與物料流速的匹配關(guān)系,實現(xiàn)能耗精準控制

This technology achieves precise energy consumption control by optimizing the matching relationship between airflow pressure and material flow rate. Taking the limestone powder project with a conveying distance of 500 meters as an example, after using a bin pump pneumatic conveying, the energy consumption per ton kilometer is reduced by 35% compared to a pneumatic lift pump, and the no-load energy consumption is reduced by 40% through intelligent start stop function. At the same time, the automatic clearing device equipped in the system can quickly handle pipeline blockages and avoid unplanned downtime losses. The actual application data of a certain aluminum industry group shows that the annual operation and maintenance cost of equipment has decreased by 60% compared to traditional conveying methods.

四、智能化升級

,賦能工業(yè)4.04

、 Intelligent upgrade, empowering Industry 4.0新一代倉泵氣力輸送系統(tǒng)深度融合物聯(lián)網(wǎng)與AI技術(shù)

The new generation of pneumatic conveying system for warehouse pumps deeply integrates IoT and AI technology to achieve intelligent control throughout the entire process. Sensor network monitors parameters such as pipeline pressure and material flow in real time, and predicts equipment health status through edge computing module. In a large cement plant, the intelligent system identified the wear trend of the warehouse pump valve in advance, extended the maintenance cycle to 18 months, and reduced the inventory cost of spare parts by 50%. In addition, the system can seamlessly integrate with platforms such as MES and ERP, providing real-time data support for production scheduling and helping enterprises build digital factories.

倉泵氣力輸送技術(shù)以“環(huán)保

The pneumatic conveying technology of warehouse pumps, with the core characteristics of "environmental protection, flexibility, efficiency, and intelligence", is reshaping the industrial ecology of industrial material conveying. From reducing material loss to reducing environmental risks, from improving production continuity to empowering intelligent manufacturing, this technology not only creates significant economic value, but also provides strong support for achieving the "dual carbon" goal. With the continuous breakthroughs in materials science and control technology, its application boundaries will be further expanded, becoming a key infrastructure for promoting industrial green transformation.

本文由倉泵友情奉獻.更多有關(guān)的知識請點擊:http://m.513951.com我們將會對您提出的疑問進行詳細的解答

This article is a friendly contribution from the pneumatic conveying system For more information, please click: http://m.513951.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

相關(guān)文章 / Recommended news

2024 濟南鑫魯泉盛機械設(shè)備有限公司 備案號:魯ICP備18012408號-3 魯公網(wǎng)安備37018102000806號

氣力輸送

氣力輸送  旋轉(zhuǎn)供料器

旋轉(zhuǎn)供料器  真空上料機

真空上料機  倉泵

倉泵  空氣懸浮磁懸浮鼓風(fēng)機

空氣懸浮磁懸浮鼓風(fēng)機  羅茨風(fēng)機

羅茨風(fēng)機  除塵器

除塵器  吸灰機/負壓除塵系統(tǒng)

吸灰機/負壓除塵系統(tǒng)  旋風(fēng)除塵器

旋風(fēng)除塵器  AV泵

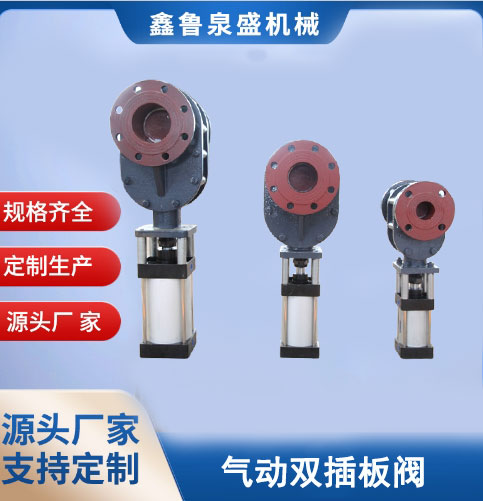

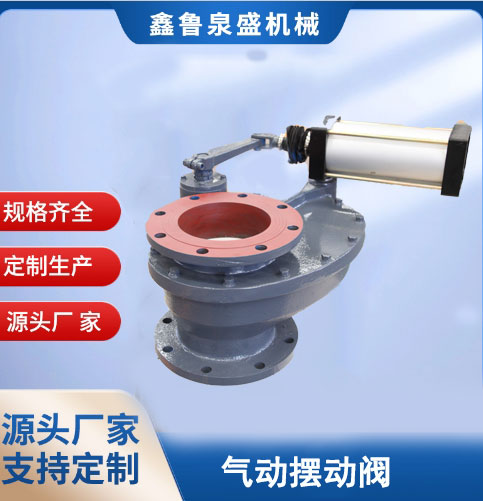

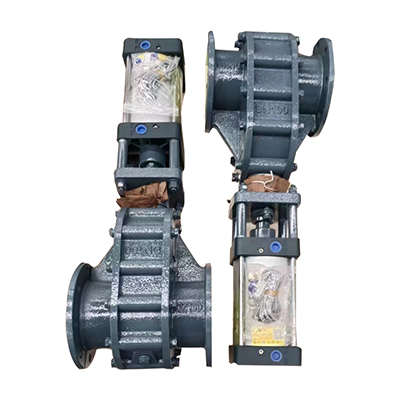

AV泵  分路閥/氣動閥門

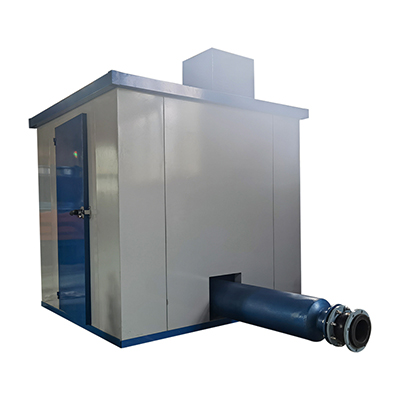

分路閥/氣動閥門  消音房

消音房  鼓風(fēng)機

鼓風(fēng)機