- 氣力輸送系統(tǒng)的構(gòu)成和應(yīng)用分類(lèi)

- 氣力輸送系統(tǒng)的運(yùn)營(yíng)流程和性能特點(diǎn)分析

- 旋轉(zhuǎn)供料器氣路系統(tǒng)解析

- 倉(cāng)泵輸送物料的保溫需求:哪些物料需保溫及原因

- 三葉羅茨鼓風(fēng)機(jī)的顯著優(yōu)勢(shì)

- 倉(cāng)泵的奧秘:從結(jié)構(gòu)形式到物料輸送之道

- 氣力輸送系統(tǒng):系統(tǒng)構(gòu)成相關(guān)解析

- 旋轉(zhuǎn)供料器工作原理及主要功能是什么?聯(lián)系我們

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司

服務(wù)熱線:15662735099

聯(lián)系地址:山東章丘棗園經(jīng)濟(jì)開(kāi)發(fā)區(qū)

拆解旋轉(zhuǎn)供料器都是由什么組成的?

旋轉(zhuǎn)供料器作為工業(yè)領(lǐng)域物料輸送的核心設(shè)備

As the core equipment for material conveying in the industrial field, the rotary feeder's structural design serves the needs of stable material transportation and precise control. The device is composed of multiple functional components, which work together to achieve continuous feeding.

1. 外殼:承載與防護(hù)的基礎(chǔ)框架

1. Shell: the basic framework for carrying and protecting

旋轉(zhuǎn)供料器的外殼通常采用碳鋼或不銹鋼材質(zhì),具備較高的強(qiáng)度與抗腐蝕性能

The shell of the rotary feeder is usually made of carbon steel or stainless steel, which has high strength and corrosion resistance. The shell has a cylindrical or square structure, with a feeding port at the top for connecting upstream material conveying pipelines, allowing materials to naturally fall into the equipment by gravity; The bottom discharge port is connected to the downstream pipeline to ensure smooth discharge of materials. Reserved inspection ports and observation windows on the shell for staff to check the internal material accumulation and maintain equipment components; Meanwhile, the sealing design of the casing can prevent material leakage and maintain a clean working environment.

2. 轉(zhuǎn)子:實(shí)現(xiàn)物料輸送的核心部件

2. Rotor: the core component for material conveying

轉(zhuǎn)子是旋轉(zhuǎn)供料器的核心執(zhí)行單元,由轉(zhuǎn)軸與多個(gè)葉片組成

The rotor is the core execution unit of the rotary feeder, consisting of a shaft and multiple blades. The blades are evenly distributed around the circumference of the shaft, forming independent material chambers. When the motor drives the shaft to rotate, the blades rotate synchronously, pushing the material entering the chamber from the inlet to the outlet. According to the material characteristics and conveying requirements, the rotor can adopt different designs: the straight blade structure is simple and suitable for materials with good fluidity; The forward leaning blade type has a stronger pushing force on materials, making it suitable for handling materials with poor viscosity or fluidity; The backward tilting blade type can reduce the compression damage of materials during transportation. In addition, a precise gap of 0.1-0.5 millimeters should be maintained between the rotor and the inner wall of the casing to balance the dual requirements of smooth material flow and leakage prevention.

3. 密封裝置:防止物料泄漏的關(guān)鍵結(jié)構(gòu)

3. Sealing device: a key structure to prevent material leakage

為避免物料在輸送中泄漏,旋轉(zhuǎn)供料器配備軸向與徑向雙重密封系統(tǒng)

To prevent material leakage during transportation, the rotary feeder is equipped with a dual axial and radial sealing system. Axial seals are located at the part where the shaft penetrates the housing, and common types include packing seals and mechanical seals. Packing seal is formed by filling the sealing chamber with elastic materials such as rubber and graphite packing, and tightly adhering to the shaft under the pressure of the gland to form a seal; Mechanical seals rely on the precise fit between the moving and stationary rings, as well as auxiliary sealing rings, to achieve efficient and long-lasting sealing effects. Radial sealing is mainly achieved through sealing plates or elastic sealing strips at the top of the blades, ensuring that the rotor blades are in close contact with the inner wall of the casing, preventing material from overflowing from the gap, thereby reducing material loss and minimizing dust pollution.

4. 驅(qū)動(dòng)系統(tǒng):提供運(yùn)轉(zhuǎn)動(dòng)力的組件組合

4. Drive system: a combination of components that provide operational power

驅(qū)動(dòng)系統(tǒng)由電機(jī)

The drive system consists of a motor, a reducer, and a transmission device, providing stable power for the feeder. As a power source, the motor can be selected from ordinary asynchronous motors or variable frequency motors according to the working conditions. The latter supports speed adjustment, making it easy to flexibly control the feeding amount. Gearboxes are used to reduce the output speed of motors and increase torque. Common types include gear reducers and worm gear reducers to adapt to the operating requirements of rotors. The transmission device is responsible for transmitting power to the rotor, belt transmission has the characteristic of buffering overload, while coupling transmission can achieve more accurate and stable power transmission, suitable for scenarios with high requirements for speed control.

5. 軸承與潤(rùn)滑系統(tǒng):保障穩(wěn)定運(yùn)行的輔助組件

5. Bearing and lubrication system: auxiliary components to ensure stable operation

軸承作為支撐轉(zhuǎn)子旋轉(zhuǎn)的關(guān)鍵部件

As a key component supporting rotor rotation, bearings are divided into two categories: rolling bearings and sliding bearings. Rolling bearings have low friction resistance and good starting performance, suitable for high-speed operating conditions; Sliding bearings have strong load-bearing capacity and impact resistance, and are commonly used in heavy-duty environments. To reduce bearing wear, the equipment is equipped with a lubrication system that forms a friction reducing oil film on the bearing surface by regularly injecting lubricating oil or grease, and takes away the heat generated during operation. Some feeders are equipped with automatic lubrication devices that can intelligently adjust the lubrication frequency based on operating time or bearing temperature, ensuring long-term stable operation of the equipment.

本文由旋轉(zhuǎn)供料器友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://m.513951.com/我們將會(huì)對(duì)您提出的疑問(wèn)進(jìn)行詳細(xì)的解答

,歡迎您登錄網(wǎng)站留言.This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

相關(guān)文章 / Recommended news

相關(guān)產(chǎn)品 / Related products

2024 濟(jì)南鑫魯泉盛機(jī)械設(shè)備有限公司 備案號(hào):魯ICP備18012408號(hào)-3 魯公網(wǎng)安備37018102000806號(hào)

氣力輸送

氣力輸送  旋轉(zhuǎn)供料器

旋轉(zhuǎn)供料器  真空上料機(jī)

真空上料機(jī)  倉(cāng)泵

倉(cāng)泵  空氣懸浮磁懸浮鼓風(fēng)機(jī)

空氣懸浮磁懸浮鼓風(fēng)機(jī)  羅茨風(fēng)機(jī)

羅茨風(fēng)機(jī)  除塵器

除塵器  吸灰機(jī)/負(fù)壓除塵系統(tǒng)

吸灰機(jī)/負(fù)壓除塵系統(tǒng)  旋風(fēng)除塵器

旋風(fēng)除塵器  AV泵

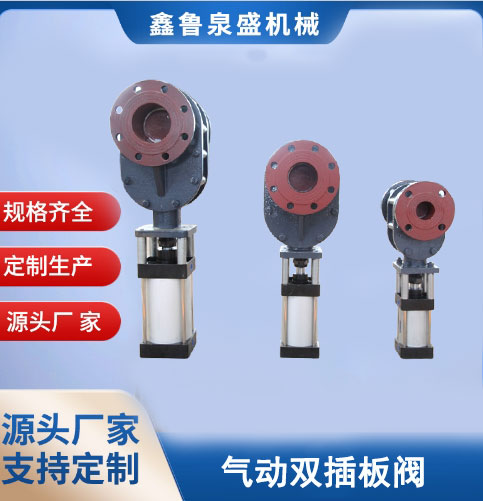

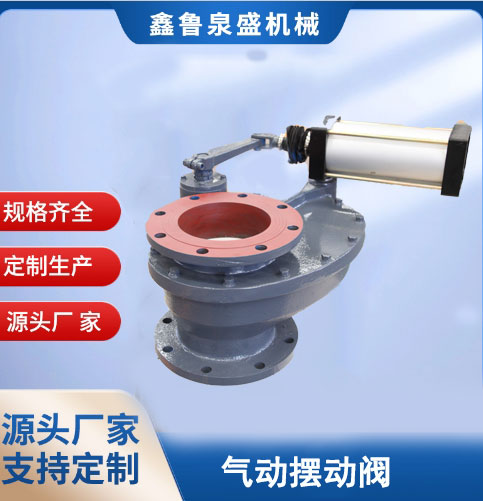

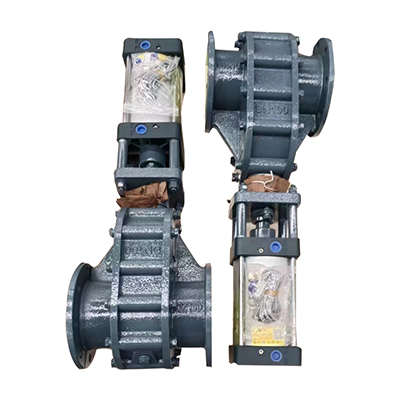

AV泵  分路閥/氣動(dòng)閥門(mén)

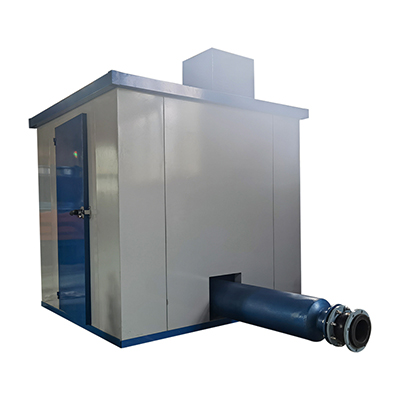

分路閥/氣動(dòng)閥門(mén)  消音房

消音房  鼓風(fēng)機(jī)

鼓風(fēng)機(jī)