旋轉供料器核心部件有什么功能?

旋轉供料器作為粉體

As the core execution unit of the powder and particle material conveying system, the precision design of the rotary feeder is reflected in the collaborative operation of the five core modules. From structural composition to functional implementation, each component carries specific technical requirements, jointly ensuring the stable operation of the equipment under complex working conditions.

一

1、 Main frame: shell and end cover

殼體:

Shell:

作為物料輸送的通道與支撐結構

As a channel and supporting structure for material transportation, the shell is made of high-strength alloy steel or stainless steel casting, with an inner wall smoothness of Ra0.4 μ m, reducing the risk of material adhesion.

進料口與出料口呈90°或180°布局

The inlet and outlet are arranged at a 90 ° or 180 ° angle to meet the connection requirements of different process pipelines. The flange interface complies with the GB/T9119 standard to ensure reliable sealing.

端蓋:

End cap:

分設于殼體兩側

Divided on both sides of the shell, it is fastened to the shell with bolts to form a closed material chamber.

快拆式端蓋設計采用液壓助力開啟機構

The quick release end cap design adopts a hydraulic assisted opening mechanism, which can be disassembled and assembled by a single person within 5 minutes, significantly reducing maintenance downtime.

二

2、 Core executing component: impeller

料腔結構:

Material cavity structure:

葉輪均布6-12個獨立料腔

The impeller is evenly distributed with 6-12 independent material chambers, and the volume of each chamber is customized according to the material packing density to ensure an accuracy of ± 1% in the amount of material transferred.

閉式葉輪適用于粉狀物料

Closed impellers are suitable for powdered materials, open impellers are suitable for granular materials, and eccentric impeller structures can reduce the compaction rate of high viscosity materials.

材質與加工:

Material and Processing:

葉輪主體采用整體鍛造工藝,關鍵部位堆焊硬質合金

The impeller body adopts integral forging technology, and the key parts are welded with hard alloy, with a hardness of HRC62 and a 5-fold increase in wear resistance.

動態(tài)平衡校正等級達G2.5

The dynamic balance correction level reaches G2.5, and the vibration value during operation is less than 1mm/s, extending the service life of the bearing.

三

3、 Power transmission module: transmission device

驅動組件:

Driver components:

電機選用IE3高效能三相異步電機

The motor is an IE3 high-efficiency three-phase asynchronous motor with a protection level of IP66, suitable for dusty and humid environments.

減速機采用行星齒輪結構

The reducer adopts a planetary gear structure, with a transmission ratio covering 1:5 to 1:100, and the output torque meets the requirements for conveying high viscosity materials.

聯(lián)軸器:

Coupling:

膜片聯(lián)軸器補償軸向/角向偏差

The diaphragm coupling compensates for axial/angular deviation, allowing a maximum offset of 0.5mm, reducing installation accuracy requirements.

配備扭矩限制器,過載時自動脫開保護傳動系統(tǒng)

Equipped with a torque limiter, it automatically disengages the protective transmission system when overloaded, and can be manually reset after troubleshooting.

四

4

機械密封:

Mechanical seal:

采用雙端面機械密封,動環(huán)為碳化硅材質

Adopting a dual end mechanical seal, the dynamic ring is made of silicon carbide material, and the static ring is made of graphite impregnated resin, with a wear resistance period of over 8000 hours.

密封沖洗系統(tǒng)可接入氮氣或清潔壓縮空氣

The sealed flushing system can be connected to nitrogen or clean compressed air, with a pressure 0.05MPa higher than the material conveying pressure, forming an air film protection.

氣封組件:

Gas seal components:

出料端配置氣封環(huán),通入干燥氣體形成正壓屏障

The discharge end is equipped with a gas seal ring, which forms a positive pressure barrier by introducing dry gas to prevent the leakage of toxic and harmful materials.

密封氣消耗量低于0.1Nm?/min,降低運行成本

The consumption of sealing gas is less than 0.1Nm?/min, reducing operating costs.

五、輔助功能模塊

5

變頻調速系統(tǒng):

Variable frequency speed regulation system:

矢量變頻器實現(xiàn)0.1Hz精度調速

The vector frequency converter achieves a precision speed regulation of 0.1Hz, with a response time of less than 50ms, suitable for the fast start stop requirements of the batching system.

配備RS485通信接口

Equipped with RS485 communication interface, it can be connected to DCS or PLC control system to achieve remote parameter setting and status monitoring.

吹掃裝置:

Blowing device:

進料口設置脈沖吹掃接口

Set up a pulse blowing interface at the feed inlet, connect the compressed air pipeline, and regularly clean the adhered material on the surface of the impeller.

吹掃壓力可調范圍0.2-0.6MPa,吹掃間隔時間通過HMI設定

The adjustable range of blowing pressure is 0.2-0.6MPa, and the blowing interval time is set through HMI to reduce manual cleaning frequency.

傳感器監(jiān)測:

Sensor monitoring:

殼體集成溫度傳感器,監(jiān)測軸承運行溫度

The shell integrates a temperature sensor to monitor the operating temperature of the bearing, triggering an alarm when it exceeds 80 ℃.

出料口配置壓力傳感器

The discharge port is equipped with a pressure sensor, which provides real-time feedback on the material conveying resistance and provides data support for closed-loop control of the system.

旋轉供料器的模塊化設計使其可通過部件選型適配多樣化物料特性與工藝需求

。從殼體材質到密封形式,從葉輪結構到傳動配置,每個組件的參數(shù)化設計共同構建起高精度、高可靠性的物料輸送解決方案,成為現(xiàn)代工業(yè)連續(xù)化生產不可或缺的關鍵設備。The modular design of the rotary feeder enables it to adapt to diverse material characteristics and process requirements through component selection. From shell material to sealing form, from impeller structure to transmission configuration, the parameterized design of each component jointly constructs a high-precision and high reliability material conveying solution, becoming an indispensable key equipment for modern industrial continuous production.

本文由旋轉供料器友情奉獻.更多有關的知識請點擊:http://m.513951.com我們將會對您提出的疑問進行詳細的解答

,歡迎您登錄網站留言.This article is a friendly contribution from the pneumatic conveying system For more information, please click: http://m.513951.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

相關文章 / Recommended news

相關產品 / Related products

2024 濟南鑫魯泉盛機械設備有限公司 備案號:魯ICP備18012408號-3 魯公網安備37018102000806號

氣力輸送

氣力輸送  旋轉供料器

旋轉供料器  真空上料機

真空上料機  倉泵

倉泵  空氣懸浮磁懸浮鼓風機

空氣懸浮磁懸浮鼓風機  羅茨風機

羅茨風機  除塵器

除塵器  吸灰機/負壓除塵系統(tǒng)

吸灰機/負壓除塵系統(tǒng)  旋風除塵器

旋風除塵器  AV泵

AV泵  分路閥/氣動閥門

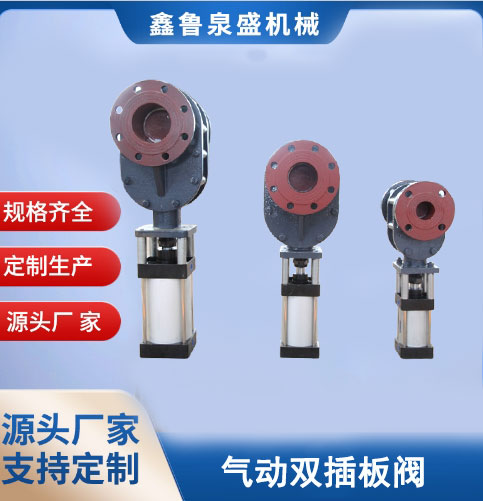

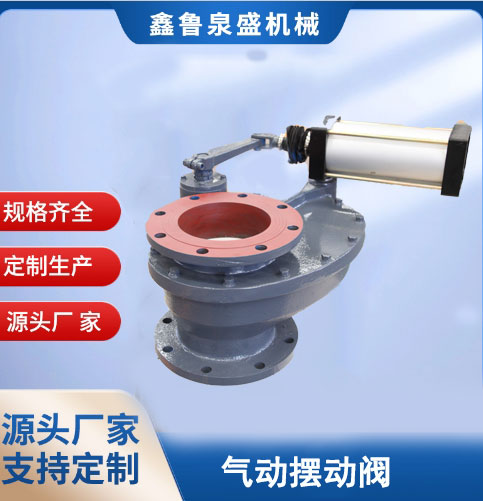

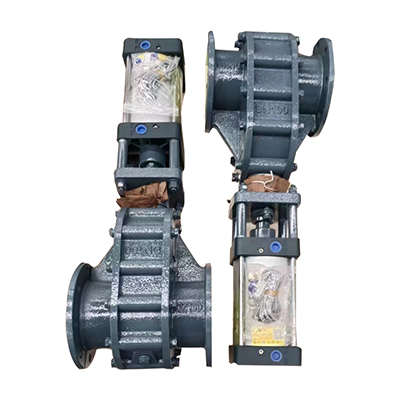

分路閥/氣動閥門  消音房

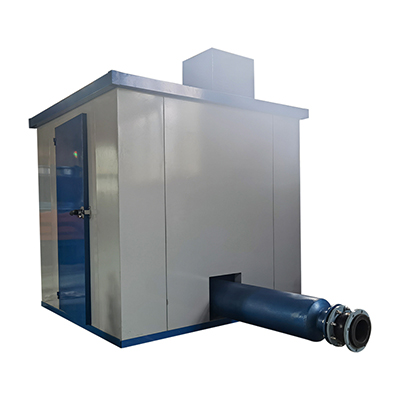

消音房  鼓風機

鼓風機